Example of Composite Sandwich Repair: Gouge in a 747 Fore Flap

Photos by Adem Rudin

Aircraft of the past were almost entirely constructed out of aluminum; however, as weight savings and fuel costs continue to rise in importance, airframe structures are being designed to use more and more lightweight composite materials. Composite sandwich structures are a key component of aircraft of today. Sandwich panels are used in the floors, bulkheads, and even the skin and wings. This article will describe the method of simple gouge repair for composite sandwich panels, and in particular, a 747 fore flap. Remember, this is a general overview, before you decide to work with composites, be sure to consult a professional, or follow the detailed repair procedures of the airframe manufacturer.

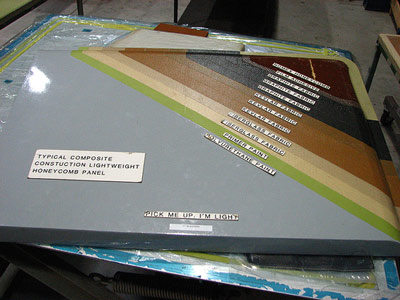

Below is an example of a common sandwich panel used in commercial airplanes.

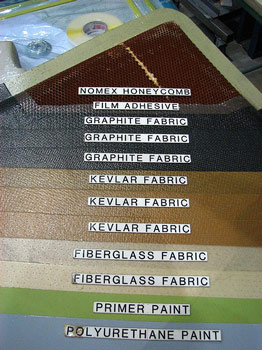

At closer look one can notice the various layers of the aerospace sandwich panel.

The core material is a Nomex honeycomb core. DuPont’s Nomex paper is used in a honeycomb structure creating an extremely fire resistant, lightweight, stiff, and strong sandwich core. However, this core alone is not strong enough. Eight layers of carbon, Kevlar, and fiberglass material are bonded to the core to increase stiffness and add impact resistance to the structure. Finally, the panel is painted with a polyurethane paint for extra UV resistance and for aesthetics. This is a good example of a common aerospace sandwich panel.

Although often lighter and stronger than similar aluminum aircraft components, composite sandwich panels are still susceptible to damage. Below is a side view of a typical 747 fore flap. Notice how the honeycomb core is curved with the skin, and the majority of the internal area is hollow.

These skins, although incredibly strong, still get damaged occasionally from baggage handlers, debris on the runway, large hail, etc. When this happens, the plane is taken to a composite repair facility where the damage is repaired as fast as possible.

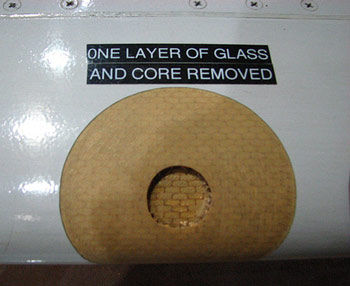

Above is a gouge similar to what could happen to an aircraft skin during use. This gouge must be repaired to prevent delamination, and the penetration of moisture.

Although difficult to see in the photo above, the gouge is centered in a concentric circle, drawn by repair personnel, with approximately an 8 inch radius. The skin within the circle will be carefully cut and removed from the honeycomb core.

After the top layer of fiber material (whether glass, Kevlar, or graphite) is removed, the damaged honeycomb core and the surrounding area is then removed.

A new honeycomb core section is cut to the appropriate size, and potted into place using special aerospace adhesive.

Three layers of fabric are then laminated over the new potted honeycomb. The first layer extends slightly past the new honeycomb insert, the second layer slightly beyond the first, and the outside layer extends to the edge of the removed skin. By laminating new fiber reinforcement material beyond the distance of the removed honeycomb, an efficient “lap joint” is created, thus preventing further damage or delamination.

The final surface is then lightly sanded to remove any excess resin, then prepped and primed for a final polyurethane coat. The wing is now repaired, and the aircraft is ready to continue service.

Home - Archive - Resources - Contact